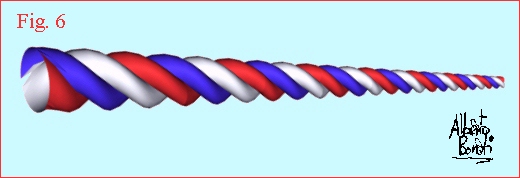

This is my 17.40 mt long windsock, max diameter is 1.40 mt and was made by 318 spinnaker gores with 106 different shapes, each utilized for white, black and red cloths.

More photography of windsock...

I used a cad-3D computer model to develope all cloth shapes for this windsock plan.

The 1

mt. long front piece a)

connect the inner round section with the following spiral parts, it's

made by 12 gores of 3 different shapes and on circular inner section

there are vents to rotate windsock.

The 13.40 mt. long median part

was

made by 10 modules

(m1-m10)

, each

composed by 30 pieces.

Each

modulus has proportional dimensions compared with previous and

following piece so that the terminal section of a module agree with

the inner section of the following one.

The 3.00 mt long last part was made by 6 gores and connect spiral section with the conical windsock end.

To obtain all cloths shapes I built a 3D cad computer model for a module and the two raccording pieces.

|

|

At first, this is the basical windsock

section ( Fi.2). At this point, I “dressed up” external surface with 3D face elements to make the required 3D model. |

|---|---|

|

|

To make shapes I copyed all 3D model measures on plan surface, obtaining in this way all 10 shapes necessary for each module. Cardboard used for a color are the same for other too. Figura 3 show these 10 pieces lies on plan surface, sewing adiacent borders together you can obtain the strange “shell” shown on Figura 4 ( b ). Three of these “shells”, identical but different in color, make a complete windsock module ( c ). |

|

|

Since all modules are proporzional in size, was enough resize shapes with cad program, plotted and stick on carboard as ( Fig. 5 ) show. |

Sewing work to joint all pieces is not easy because all seams are not straight, it's necessary to mark some refferring points on borders and use them for control during sewing work.

|

|

Cause of his concave angle section, this kind of windsock lean to inflate too much and lose his form. To avoid this problem, I added a rope on each section to link the three internal vertex (a-a-a on Figura 7 ) as shown on side picture. |

![]()

|

|

2007 by |

|

e-mail : kites_webmaster@libero.it |